Products

LCP

Category:Special Plastic Film

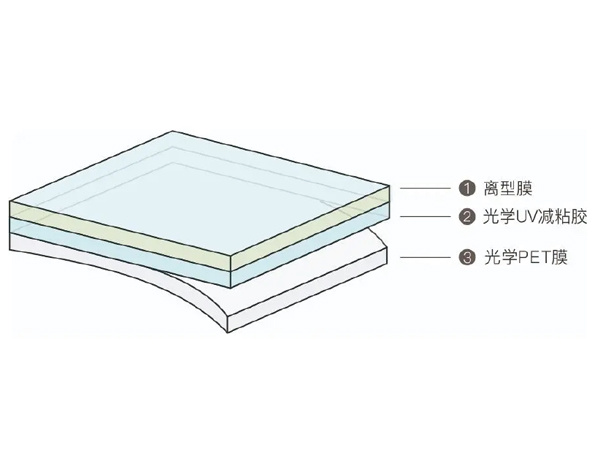

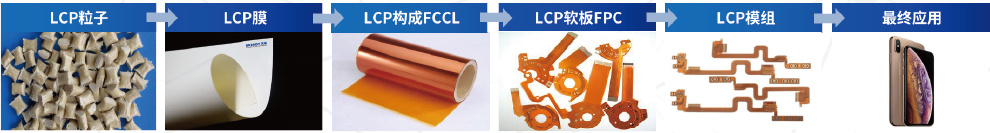

This product can maintain a constant dielectric constant at high frequencies; The tangent loss is very small, making it very suitable for millimeter wave applications; The thermal expansion is very small and can be used as an ideal high-frequency packaging material. It can be processed into Flexible Printed Circuits (FPCs) to achieve high-speed transmission of high-frequency signals, mainly used in antenna modules for products such as smartphones, autonomous driving, and wearable devices, and has broad market prospects.

LCP Details Description

Modern communication technology uses high-frequency and high-speed signals, which have higher requirements for the dielectric constant and electrical loss of materials.

This product can maintain a constant dielectric constant at high frequencies; The tangent loss is very small, making it very suitable for millimeter wave applications; The thermal expansion is very small and can be used as an ideal high-frequency packaging material. Flexible Printed Circuits (FPCs) can be connected to achieve high-speed transmission of high-frequency signals, mainly used in antenna modules for products such as smartphones, autonomous driving, and wearable devices, and have broad market prospects.

Upstream and Downstream Industries

Application Area

Performance Parameter

|

Items |

Unit |

Test method |

Bready H-LCPF |

Bready L-LCPF |

|

Tensile Strength |

MPa |

HD-B604B-S |

MD 260 |

MD 249 |

|

TD 205 |

TD 148 |

|||

|

Elongation at Break |

% |

HD-B604B-S |

MD 40 |

MD 36 |

|

TD 45 |

TD 21 |

|||

|

Tensile Modulus |

MPa |

HD-B604B-S |

MD 4316 |

MD 4600 |

|

TD4212 |

TD4670 |

|||

|

Thermal Expansion Coefficient |

ppm/c |

TATMA450 30-250℃ |

MD16 |

MD18 |

|

TD20 |

TD20 |

|||

|

Melting Point |

℃ |

TA DSC 25 |

330 |

280 |

|

Surface Resistivity |

Ω |

GB/T 31838.2-2019 |

5.00E+16 |

4.00E+16 |

|

Volume Resistivity |

Ω.cm |

GB/T 31838.2-2019 |

2.00E+16 |

3.00E+16 |

|

Water Absorption Rate |

% |

Bready method (25℃, 50%R.H.) |

0.03 |

0.03 |

|

Dielectric Constant DK |

|

MS46122B Frequency 28GHz |

3.3 |

3.4 |

|

Dissipation Coefficient |

|

|

0.0019 |

0.002 |

Related Products

Online Consult